SureLok & Movement Joints

Surelok

SURELOK™ the complete engineered solution for temporary movement joints

The SureLokTM TMJ System Encompasses 8 Products

| SureLokTM | 200S | 160S | 200W | 160W | 200R | 160R | 200BRS | 160BRS |

| Propping can be removed prior to grouting | ✔ | ✖ | ✔ | ✖ | ✔ | ✖ | ✔ | ✖ |

| Slab to Slab connection | ✔ | ✔ | ✖ | ✖ | ✔ | ✔ | ✖ | ✖ |

| Slab to Wall connection | ✖ | ✖ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| No pour strips | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| No corbels | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Most economical TMJ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Simple installation | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Reduced construction time | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Improved job site safety | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Slab thickness between 160 and 195mm | ✖ | ✔ | ✖ | ✔ | ✖ | ✔ | ✖ | ✔ |

| Slab thickness of 200mm and above | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Suitable for existing structures | ✖ | ✖ | ✖ | ✖ | ✔ | ✔ | ✖ | ✖ |

Purpose & Performance

SureLok™ is the result of years of experience, investment, research, development and testing. It has been developed for the post-tensioning, construction and mining industries with a patent pending in Australia and internationally. SureLok™ is revolutionary as it offers a range of safety, cost, design and performance benefits. It is a world class leader in the industry as it is the first solution that provides bi-directional temporary movement and two-axis load transfer, all within a fully sealed component.

The SureLok™ Slab to Slab range includes two SureLok™ products. The SureLok™ 200S allows the back-propping to be removed when concrete strength achieves 32MPa, and the SureLok™ 160S is able to fit into slabs thinner than 200mm. The SureLok™ 200R and the SureLok™ 160R are post fixed retrofit systems. Both products are designed to provide a TMJ between a slab to wall or slab to slab where the bars need to be epoxied into an existing structure.

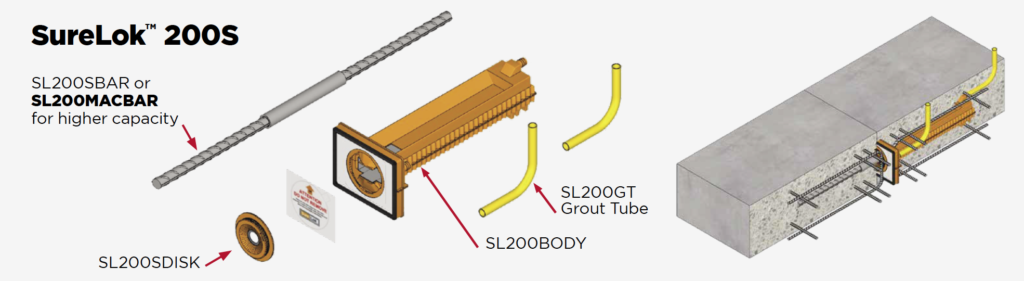

Slab to Slab Components

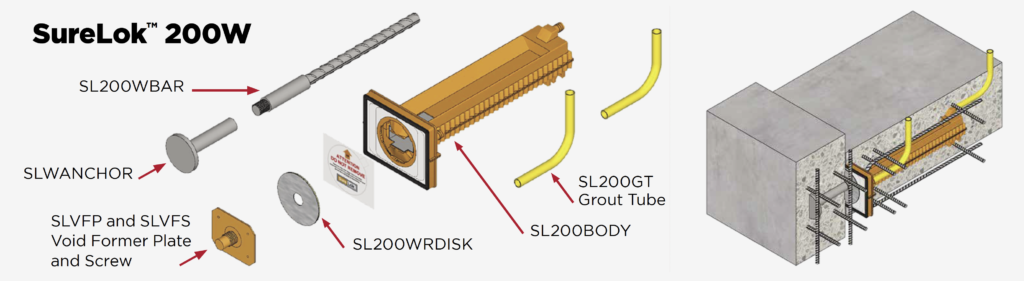

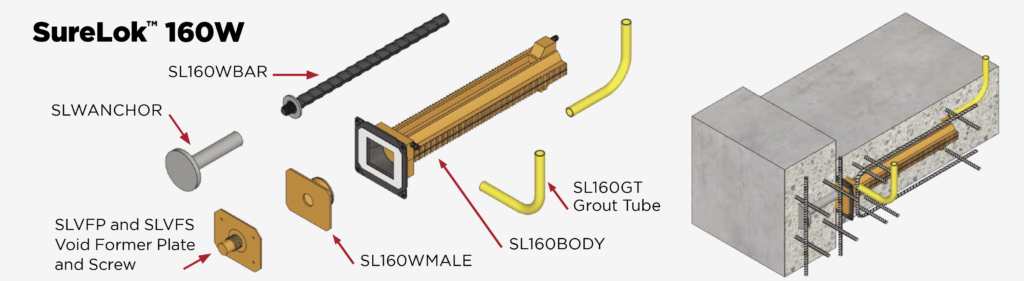

The SureLok™ Slab to Wall range encompasses four SureLok™ products. The SureLok™ 200W, the SureLok™ 160W, the SureLok™ 200BRS and the SureLok™ 160BRS. All four products are designed to provide a TMJ between a slab and wall and eliminate the requirement for pour strips. The SureLok™ 200W and SureLok™ 160W are used in applications where the anchor can be fixed inside the formwork and secured with a nailing plate or by local reinforcement. These systems are also used in precast walls. The SureLok™ BRS systems are used for basement applications where the walls are applied using shotcrete.

Sizes and Dimensions

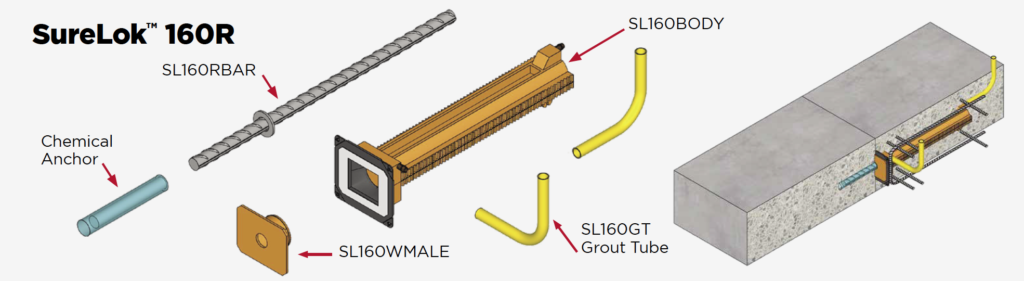

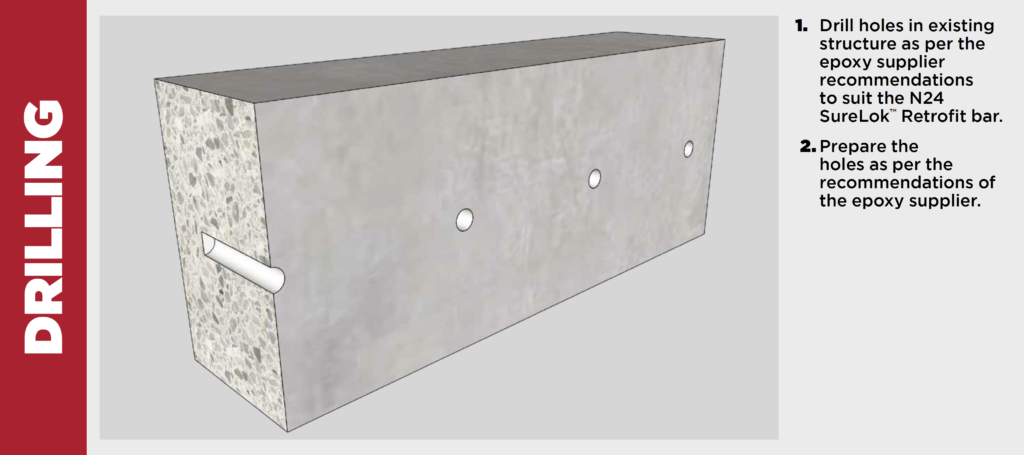

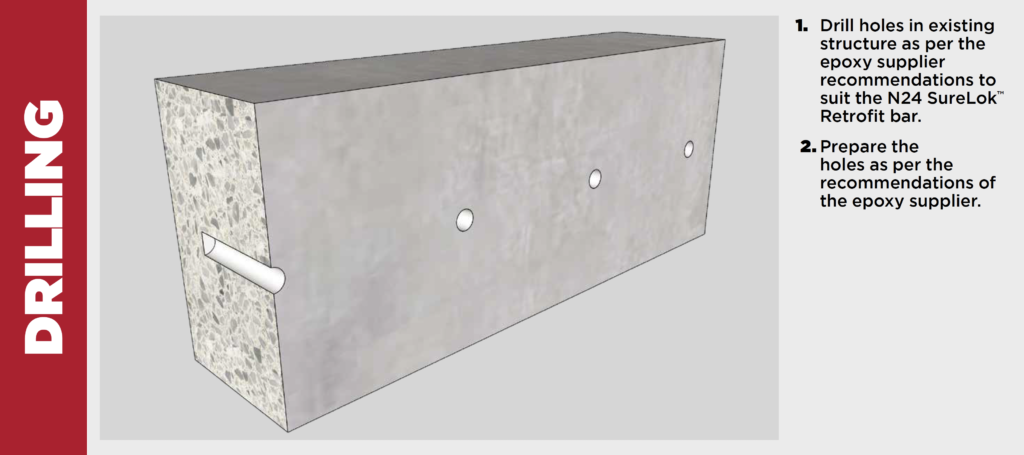

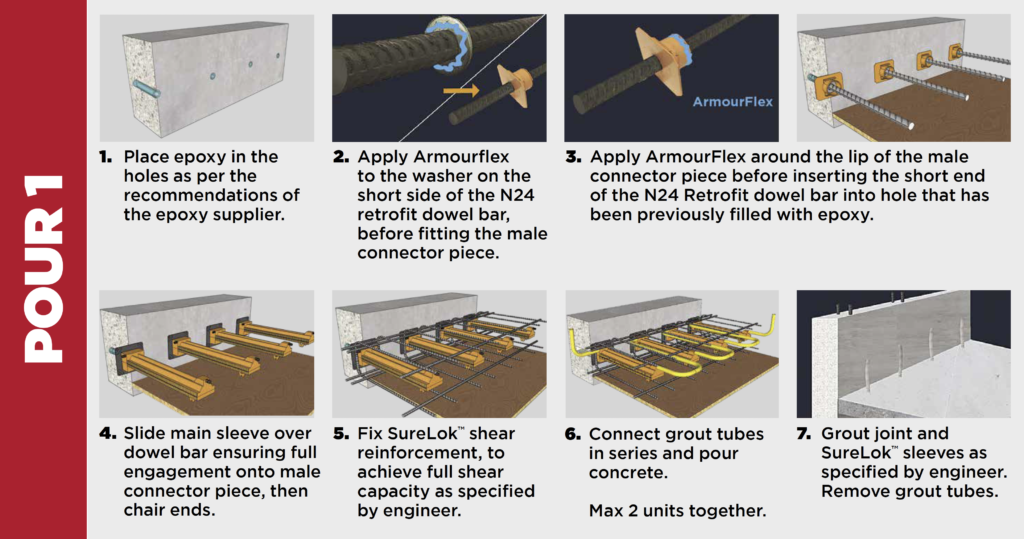

SureLok™ Retrofit, the SureLok™ 200R and the SureLok™ 160R are post fixed retrofit systems. Both products are designed to provide a TMJ between a slab to wall or slab to slab where the bars need to be epoxied into an existing structure.

SureLokTM 200R RETROFIT

Notes:

1. Grout tubes can link or connect maximum 2 units together for grouting. Always assess the risk of connecting multiple units together.

2. Grouting must be carried out under low pressure.

3. Each SureLok™ unit must utilise the 2 grout ports, one port as an inlet and the other as an outlet so as grout flows from one end of the unit to the other. Grout can flow in any direction along the SureLok™ unit.

4. Grout mix must achieve 40MPa to ensure the full tension capacity is achieved.

SureLokTM 160R RETROFIT

Notes:

1. Grout tubes can link or connect maximum 2 units together for grouting. Always assess the risk of connecting multiple units together.

2. Grouting must be carried out under low pressure.

3. Each SureLok™ unit must utilise the 2 grout ports, one port as an inlet and the other as an outlet so as grout flows from one end of the unit to the other. Grout can flow in any direction along the SureLok™ unit.

4. Grout mix must achieve 40MPa to ensure the full tension capacity is achieved.