Rebar Couplers

Lenton

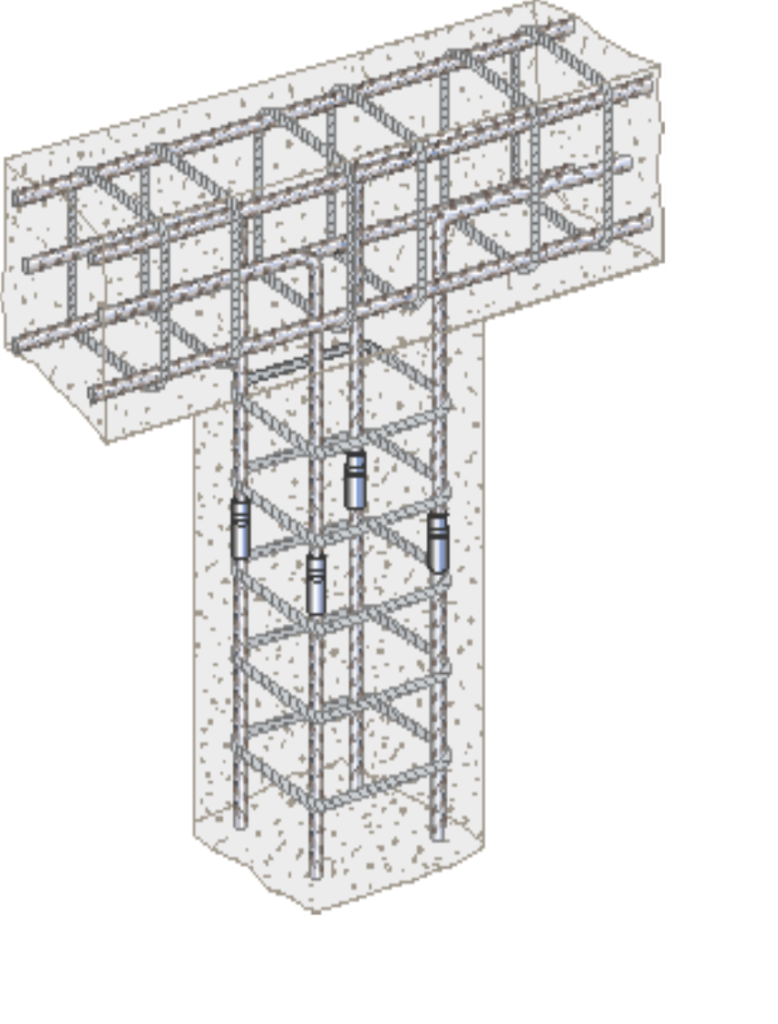

nVent LENTON mechanical splices reduce congestion, and are ideal for fast and easy rebar placing when using sliding or climbing formwork.

Purpose & Performance

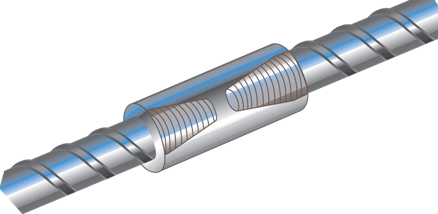

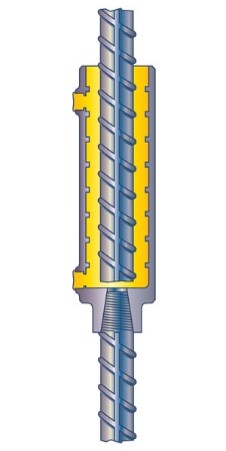

nVent LENTON Mechanical Splices, are a taper-threaded splicing system that assures a positive locking connection, providing continuity and structural integrity to reinforced concrete construction. nVent LENTON spliced bars behave as continuous lengths of reinforcing steel bars by providing “full strength” in tension, compression and stress reversal applications.

The nVent LENTON self-aligning, taper-threaded design provides ease of installation, consistent performance and durability. It also develops higher tensile strength than lap splicing and provides full load transfer with the slimmest and shortest coupler possible.

nVent LENTON Standard Couplers are designed to splice the same diameter bars where at least one bar is free to be rotated and is not restricted in its axial direction. The couplers are machined to have taper threads at both ends, creating a mechanical butt splice of two sections of reinforcing steel.

Features

- Designed to splice the same diameter bars where the second bar can be rotated and is not restricted in its axial direction

- Slim design maintains concrete cover

- Installs quickly and easily

Sizes and Dimensions

Standard Couplers – A12. Standard in Europe, The Middle East, Africa, Asia, and Australia.

| Rebar Size Designation Metric | Part No. | “A” | “B” | “D” | Weight |

| mm | mm | mm | mm | kg | |

| 10 | EL10A12 | 17* | 49 | 18 | 0.07 |

| 12 | EL12A12 | 17* | 50 | 19 | 0.06 |

| 14 | EL14A12 | 22* | 56 | 21 | 0.13 |

| 16 | EL16A12 | 22* | 61 | 24 | 0.13 |

| 18 | EL18A12 | 27* | 72 | 29 | 0.25 |

| 20 | EL20A12 | 27* | 87 | 35 | 0.27 |

| 22 | EL22A12 | 30* | 91 | 37 | 0.35 |

| 25 | EL25A12 | 35 | 97 | 40 | 0.44 |

| 28 | EL28A12 | 40 | 101 | 42 | 0.61 |

| 30 | EL30A12 | 40 | 121 | 52 | 0.69 |

| 32 | EL32A12 | 45 | 108 | 45 | 0.79 |

| 34 | EL34A12 | 45 | 128 | 55 | 0.89 |

| 36 | EL36A12 | 50 | 121 | 52 | 1.08 |

| 38 | EL38A12 | 55 | 124 | 53 | 1.41 |

| 40 | EL40A12 | 55 | 131 | 57 | 1.40 |

| 43 | EL43TA12 | 60 | 158 | 66 | 2.07 |

| 50 | EL50TA12 | 70 | 166 | 70 | 2.91 |

| 57 | EL57TA12 | 80 | 192 | 83 | 4.45 |

* Use hex material (measured across the flats), others use round material.

** Available in select regions in U.S.

LENTON Positional couplers are designed to splice two curved, bent, or straight bars of the same diameter, when neither bar can be rotated.

Typical applications include bent bar, prefabricated cages and precast structural elements.

Sizes and Dimensions

Position Couplers – P13L. Standard in Europe, The Middle East, Africa, Asia, and Australia.

| Rebar Size Designation Metric | Part No. | “A” | “B” | “Fc” | Max. | “D” | Weight |

| mm | mm | mm | mm | Fo | mm | kg | |

| 10 | EL10P13L | 25 | 70 | 50 | 85 | 18 | 0.36 |

| 12 | EL12P13L | 25 | 75 | 49 | 85 | 19 | 0.36 |

| 14 | EL14P13L | 25 | 82 | 51 | 90 | 21 | 0.37 |

| 16 | EL16P13L | 30 | 88 | 56 | 97 | 24 | 0.59 |

| 18 | EL18P13L | 35 | 100 | 61 | 107 | 29 | 0.85 |

| 20 | EL20P13L | 35 | 125 | 73 | 135 | 35 | 1.09 |

| 22 | EL22P13L | 40 | 132 | 77 | 141 | 37 | 1.55 |

| 25 | EL25P13L | 45 | 140 | 80 | 146 | 40 | 1.94 |

| 28 | EL28P13L | 50 | 147 | 83 | 151 | 42 | 2.53 |

| 30 | EL30P13L | 55 | 169 | 93 | 171 | 52 | 3.35 |

| 32 | EL32P13L | 60 | 156 | 93 | 164 | 45 | 3.96 |

| 34 | EL34P13L | 60 | 177 | 103 | 184 | 55 | 4.28 |

| 36 | EL36P13L | 65 | 172 | 99 | 177 | 52 | 5.01 |

| 38 | EL38P13L | 70 | 174 | 103 | 183 | 53 | 6.05 |

| 40 | EL40P13L | 70 | 184 | 106 | 190 | 57 | 6.18 |

| 43 | EL43TP13L | 75 | 213 | 127 | 219 | 66 | 8.24 |

| 50 | EL50TP13L | 90 | 224 | 135 | 230 | 70 | 11.71 |

| 57 | EL57TP13L | 100 | 256 | 148 | 257 | 83 | 17.11 |

* Use hex material (measured across the flats), others use round material.

Transition Couplers are designed to splice different diameter bars where one bar can be rotated and the bar is not restricted in its axial direction.

Sizes and Dimensions

Transition Couplers – A12. Standard in Europe, The Middle East, Africa, Asia, and Australia.

| Rebar Size Designation Metric | Part No. | “A” | “B” | “DL“ | “DS“ | Weight |

| mm | mm | mm | mm | mm | kg | |

16 – 12 | EL1612A12 | 22* | 61 | 24 | 19 | 0.14 |

| 16 – 14 | EL1614A12 | 22* | 64 | 24 | 21 | 0.14 |

20 – 16 | EL2016A12 | 27* | 80 | 35 | 24 | 0.27 |

22 – 20 | EL2220A12 | 30* | 95 | 37 | 35 | 0.38 |

25 – 20 | EL2520A12 | 35 | 98 | 40 | 35 | 0.50 |

25 – 22 | EL2522A12 | 35 | 100 | 40 | 37 | 0.49 |

28 – 20 | EL2820A12 | 40 | 101 | 42 | 35 | 0.69 |

28 – 25 | EL2825A12 | 40 | 105 | 42 | 40 | 0.67 |

32 – 25 | EL3225A12 | 45 | 109 | 45 | 40 | 0.91 |

32 – 28 | EL3228A12 | 45 | 111 | 45 | 42 | 0.88 |

36 – 32 | EL3632A12 | 50 | 120 | 52 | 45 | 1.15 |

40 – 32 | EL4032A12 | 55 | 126 | 57 | 45 | 1.50 |

43 – 40 | EL43T40A12 | 60 | 152 | 66 | 57 | 2.07 |

50 – 32 | EL50T32A12 | 70 | 147 | 70 | 45 | 3.00 |

*Use hex material (measured across the flats), others use round material.

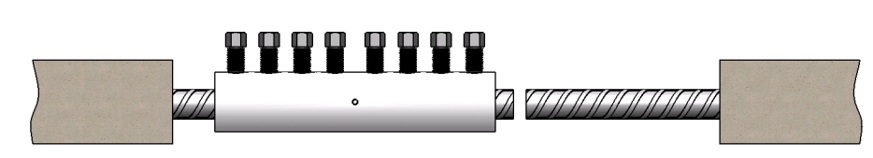

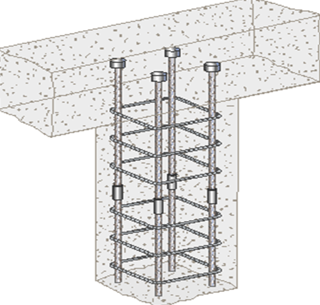

nVent LENTON Lock is an in-situ reinforcing steel bar splice that requires no bar end preparation. It is ideal for new construction, repair or retrofit applications. nVent LENTON Lock features gripping technology that provides for the development of full reinforcing bar (rebar) strength and improved overall structural integrity in tension, compression, stress-reversal and dynamic applications. nVent LENTON Lock is designed for use in column splicing, bridge applications, piling, splicing to protruding dowels cast in concrete, closure pours, beams, and other demanding splicing applications.

Features

- Designed to meet or exceed ACI318, International Building Codes and Department of Transportation requirements

- Requires no bar end preparation

- Provides superior fatigue performance

- Performs like a continuous piece of bar

- Installs quickly and easily using simple, off-the-shelf hand tools

- Works with a variety of international reinforcing bar grades and sizes

Product Specifications

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| Inch-Lb* | Metric* | Canadian | Soft Metric | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | ||||

| – | 10 | – | 10 | LL12B1 | 5.0 | 127 | 1.1 | 29 | 0.6 | 15 | 1.2 | 0.6 | 1/2 | 13 | 150 | 205 | 6 |

| #4 | 12 | 10M | 10 | LL12B1 | 5.0 | 127 | 1.1 | 29 | 0.6 | 15 | 1.2 | 0.6 | 1/2 | 13 | 150 | 205 | 6 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| – | 14 | – | – | LL16B1 | 6.3 | 159 | 1.4 | 35 | 0.7 | 19 | 2.1 | 0.9 | 1/2 | 13 | 150 | 205 | 6 |

| #5 | 16 | 15M | 16 | LL16B1 | 6.3 | 159 | 1.4 | 35 | 0.7 | 19 | 2.1 | 0.9 | 1/2 | 13 | 150 | 205 | 6 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| – | 18 | – | – | LL20B1 | 7.5 | 191 | 1.6 | 41 | 0.9 | 24 | 3.2 | 1.4 | 1/2 | 13 | 150 | 205 | 6 |

| #6 | 16 | 15M | 16 | LL16B1 | 7.5 | 191 | 1.6 | 41 | 0.9 | 24 | 3.2 | 1.4 | 1/2 | 13 | 150 | 205 | 6 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| #7 | 22 | – | 22 | LL22B1 | 8.7 | 222 | 1.9 | 48 | 1.1 | 28 | 5.2 | 2.3 | 5/8 | 16 | 250 | 340 | 8 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| #8 | 25 | 25M | 25 | LL25B1 | 10 | 254 | 2.1 | 54 | 1.2 | 30 | 7.4 | 3.4 | 5/8 | 16 | 350 | 475 | 8 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| #9 | 28 | 30M | 29 | LL28B1 | 11.3 | 287 | 2.4 | 60 | 1.3 | 34 | 10.2 | 4.6 | 5/8 | 16 | 350 | 475 | 10 |

| – | 30 | – | – | LL28B1 | 11.3 | 287 | 2.4 | 60 | 1.3 | 34 | 10.2 | 4.6 | 5/8 | 16 | 350 | 475 | 10 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| #10 | 32 | – | 32 | LL32B1 | 12.7 | 323 | 2.6 | 65 | 1.5 | 38 | 13.1 | 5.9 | 13/16 | 21 | 500 | 680 | 8 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| – | 34 | – | – | LL36B1 | 14.1 | 358 | 2.8 | 72 | 1.7 | 43 | 17.3 | 7.9 | 13/16 | 21 | 550 | 750 | 10 |

| #11 | 36 | 35M | 36 | LL36B1 | 14.1 | 358 | 2.8 | 72 | 1.7 | 43 | 17.3 | 7.9 | 13/16 | 21 | 550 | 750 | 10 |

| Rebar Designation | Rebar Designation | Rebar Designation | Rebar Designation | Coupler Part Number | Length (L) | Length (L) | Outside Diameter (d) | Outside Diameter (d)A | Inside Diameter | Inside Diameter | Weight | Weight | Socket Size | Socket Size | Average Torque All Bolts | Average Torque All Bolts | Number of Bolts |

| – | 38 | – | – | LL40B1 | 15.7 | 400 | 3.1 | 80 | 1.9 | 47 | 24.0 | 10.9 | 13/16 | 21 | 580 | 790 | 12 |

| – | 40 | – | – | LL40B1 | 15.7 | 400 | 3.1 | 80 | 1.9 | 47 | 24.0 | 10.9 | 13/16 | 21 | 550 | 750 | 12 |

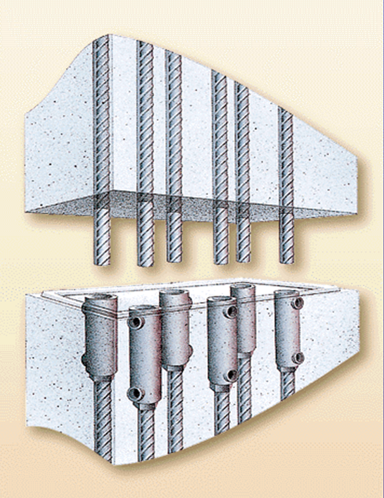

nVent LENTON Interlok was engineered for use in precast construction. It is designed to provide structural integrity between load bearing precast concrete elements such as columns, beams, shear walls, and panels. nVent LENTON Interlok provides superior dynamic, seismic and ultimate strength performance for moment frame applications.

Typical applications include column to column, column to foundation, shearwall to foundation, shearwall to shearwall, panel to panel, wall to floor slab and architectural panels.

Features

- Maintains structural integrity between precast sections.

- Provides load path continuity – reinforcing steel bars (rebar) act as one continuous bar.

- Tensile loads are transferred through the reinforcing bar independent of the compressive strength of the concrete.

- Helps eliminate costly and unsightly patchwork.

- Designed to meet or exceed building code requirements.

- Easy to use.

Sizes and Dimensions

| Rebar Designation | Rebar Designation | Rebar Designation | No. of Couplers per Bag of HY10L Grout | Part No. | Art No. | A | A | B | B | C | C | D | D | E | E |

| Inch-Lb | Metric | Canadian | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | |||

| #5 | 16 | 15M | 24 | LK5 | 145575 | 7-13/16 | 199 | 2-9/16 | 65 | 6-1/8 | 156 | 7/8 | 22 | 1-7/8 | 48 |

| #6 | 20 | 20M | 25 | LK6 | 145580 | 7-13/16 | 199 | 2-9/16 | 65 | 6-1/8 | 156 | 1-1/8 | 29 | 1-7/8 | 48 |

| #7 | 22 | – | 26 | LK7 | 145585 | 7-13/16 | 199 | 2-9/16 | 65 | 6-1/8 | 156 | 1-1/4 | 32 | 1-7/8 | 48 |

| #8 | 25 | 25M | 21 | LK8 | 145590 | 8-5/8 | 219 | 2-11/16 | 68 | 7 | 178 | 1-3/8 | 35 | 2 | 51 |

| #9 | 28 | 30M | 17 | LK9 | 145595 | 9-3/4 | 248 | 2-13/16 | 72 | 8 | 203 | 1-1/2 | 38 | 2-1/8 | 54 |

| #10 | 32 | – | 13.5 | LK10 | 145600 | 10-13/16 | 275 | 3 | 76 | 9 | 229 | 1-9/16 | 40 | 2-5/16 | 59 |

| #11 | 36 | 35M | 11.5 | LK11 | 145605 | 11-15/16 | 303 | 3-1/8 | 79 | 9-7/8 | 251 | 1-11/16 | 43 | 2-7/16 | 62 |

| 40 | – | 7 | LK40 | 145610 | 15-3/16 | 386 | 3-11/16 | 94 | 12-3/4 | 324 | 2-1/4 | 58 | 2-3/4 | 70 | |

| #14 | 43 | 45M | 7 | LKT14 | 145611 | 15-3/16 | 386 | 3-11/16 | 94 | 12-3/4 | 324 | 2-1/8 | 54 | 2-3/4 | 70 |

| 50 | – | 4 | LKT50 | 145615 | 20-5/16 | 516 | 4-1/2 | 114 | 17 | 432 | 2-3/4 | 71 | 3-1/4 | 83 | |

| #18 | 57 | 55M | 4.5 | LKT18 | 145620 | 20-5/16 | 516 | 4-1/2 | 114 | 17 | 432 | 2-3/4 | 70 | 3-1/4 | 83 |

The system is designed to meet or exceed the ACI ® and IBC ® codes for Type 1 and Type 2 mechanical connections. The system is also designed to meet the requirements of

AS3600, BS 8110, BS EN1992-1-1, BRL 504, and Hong Kong GS, in addition to other worldwide codes.

The nVent LENTON Terminator provides an alternative to hooked rebar, or an anchor or stop nut for rebar passing through a pile plank or structural steel element. The front face of the coupler is generously designed to carry the full tension load of the rebar when the anchor is bearing against concrete or structural steel.